O-Rings are among the most widely used sealing components in industrial machinery. Their simple design, reliable performance, and adaptability to different operating conditions make them a core element in countless mechanical systems. From heavy-duty hydraulic equipment to precision automation systems, O-Rings help prevent leakage, maintain pressure, and protect internal components from contamination.

This article explores the most common applications of O-Rings in industrial machinery, explains why they are so widely adopted, and discusses when custom sealing design becomes necessary to meet more demanding requirements.

Why O-Rings Are Essential in Industrial Machinery

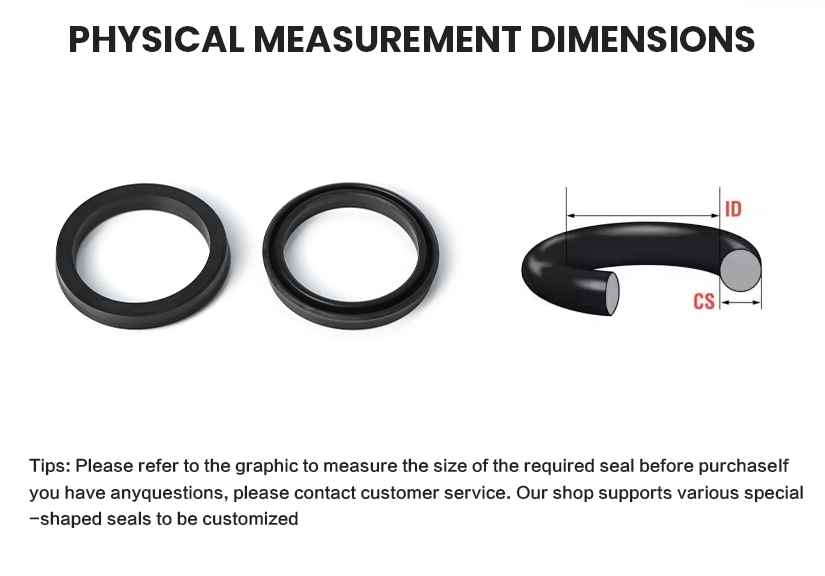

An O-Ring is a circular elastomer seal with a round cross-section, designed to sit in a groove and create a tight seal when compressed. Despite their simplicity, O-Rings perform critical functions in industrial equipment where reliability and consistency are required.

Key reasons for their widespread use include:

-

Simple and compact design

-

Effective sealing for both static and dynamic applications

-

Compatibility with many materials and media

-

Ease of installation and maintenance

In industrial machinery, even a minor seal failure can lead to downtime, safety risks, and increased operating costs. O-Rings provide a dependable sealing solution across a broad range of applications.

Hydraulic Systems

Cylinders and Actuators

Hydraulic cylinders are one of the most common applications for O-Rings. They are used to seal pistons, rods, and end caps, ensuring that hydraulic fluid remains contained under pressure.

In these applications, O-Rings must withstand:

-

High pressure

-

Repeated reciprocating motion

-

Contact with hydraulic oil

When properly selected, O-Rings provide effective sealing while maintaining low friction and long service life.

Valves and Manifolds

O-Rings are also widely used in hydraulic valves and manifolds to seal internal passages and prevent cross-leakage between circuits. Their compact size allows them to fit into tight spaces while maintaining reliable sealing performance.

Pneumatic Equipment

Air Cylinders

In pneumatic systems, O-Rings are commonly used in air cylinders to seal pistons and end caps. Although pneumatic systems typically operate at lower pressures than hydraulic systems, sealing reliability is still critical for maintaining efficiency and response time.

O-Rings in pneumatic applications benefit from:

-

Good elasticity

-

Low leakage rates

-

Stable performance under frequent cycling

Control Valves and Connectors

O-Rings are widely used in pneumatic valves, quick connectors, and fittings. Their ability to seal compressed air without excessive friction makes them ideal for high-cycle applications.

Pumps and Compressors

Fluid Pumps

O-Rings play an important role in sealing pump housings, shafts, and covers. They help prevent fluid leakage and maintain internal pressure, which is essential for pump efficiency.

Depending on the pumped media, O-Rings may need to resist oil, water, chemicals, or gas. Material selection is therefore critical in these applications.

Air and Gas Compressors

In compressors, O-Rings are used to seal joints and internal components exposed to pressure and temperature fluctuations. Properly designed O-Ring seals help reduce leakage and improve overall system performance.

Industrial Gearboxes and Transmissions

Gearboxes and transmissions rely on O-Rings to seal covers, inspection ports, and shaft interfaces. These components are often exposed to lubricating oils, vibration, and temperature changes.

O-Rings in these systems must provide:

-

Long-term oil resistance

-

Dimensional stability

-

Reliable sealing under vibration

Failure of a single O-Ring in a gearbox can lead to oil leakage and accelerated wear of internal components.

Industrial Automation and Robotics

In automation equipment and robotic systems, O-Rings are used in actuators, sensors, and fluid control components. These systems often require precise motion and repeatable performance.

O-Rings help maintain consistent pressure and protect sensitive components from dust and contaminants. Their compact size and flexibility make them suitable for modern, space-efficient machine designs.

Power Generation and Energy Equipment

O-Rings are also widely used in energy-related equipment, including power generation systems and auxiliary machinery. In these environments, seals may be exposed to high temperatures, pressure variations, and aggressive media.

Standard O-Rings may perform well in normal conditions, but extreme environments often require specially designed materials and geometries.

When Standard O-Rings Reach Their Limits

While standard O-Rings cover a wide range of industrial applications, they are not always sufficient. Certain conditions can push standard seals beyond their design limits, such as:

-

Extremely high or low temperatures

-

Aggressive chemicals or gases

-

High-pressure cycling

-

Unusual groove designs or installation constraints

In these cases, relying on off-the-shelf O-Rings may lead to premature failure.

Custom Sealing Design for Industrial Machinery

Custom sealing design provides a solution when standard O-Rings cannot meet specific application requirements. At Hao Seal Technology, custom sealing design focuses on developing seals that are tailored to the actual operating conditions of each machine.

The process begins with a detailed analysis of:

-

Operating pressure and temperature

-

Media compatibility

-

Motion type and speed

-

Installation environment

-

Special requirements such as electrical conductivity or insulation

Based on this information, seal geometry and material selection are optimized to ensure reliable performance.

Customized Mold and In-House Rubber Compounds

Custom O-Rings often require non-standard dimensions or special cross-sections. Through customized mold development, seals can be manufactured to match unique groove designs and space limitations.

Equally important is the development of the rubber compound itself. In-house compound formulation allows seals to be engineered for:

-

Resistance to oil, gas, or liquids

-

High or low temperature performance

-

Improved wear and aging resistance

-

Conductive or insulating properties

This integrated approach ensures that both shape and material contribute to long-term sealing reliability.

Practical Benefits of Custom O-Rings

For industrial machinery operating under demanding conditions, custom O-Rings offer clear advantages:

-

Improved sealing performance

-

Longer service life

-

Reduced maintenance and downtime

-

Better overall equipment reliability

These benefits are especially valuable in heavy machinery, continuous production lines, and mission-critical systems.

Conclusion

O-Rings are a fundamental component in industrial machinery, used across hydraulic systems, pneumatic equipment, pumps, gearboxes, and automation technology. Their simplicity and versatility make them indispensable in modern industry.

However, when operating conditions become extreme or highly specific, standard O-Rings may no longer be sufficient. Custom sealing design—supported by customized molds and in-house rubber compound development—provides a reliable solution for these challenges.

For a closer look at standard and custom O-Ring solutions, selecting the right partner can make a critical difference in equipment performance and longevity.

https://www.haosealtech.com/O-Ring/

R&D