High-performance OEM circuits demand components that reduce switching losses while maintaining voltage reliability. Super Fast Recovery Diodes (FRDs) offer ultra-short reverse recovery times and higher voltage handling, making them ideal for high-frequency inverters, EV charging modules, pulse power circuits, and high-speed rectification designs. This guide focuses on practical strategies for integrating FRDs into OEM circuits to accelerate prototyping and optimize performance.

1. Optimizing Circuit Layout for FRD Integration

Effective FRD integration starts with PCB layout:

-

Minimize Parasitic Inductance: Use wide, short traces and minimize lead lengths to prevent voltage overshoot.

-

Strategic Placement: Position FRDs close to switching devices like MOSFETs or IGBTs to reduce conduction path resistance.

-

Thermal Paths: Implement copper pours, thermal vias, or small heat sinks to manage localized heating in high-frequency switching nodes.

-

Grounding Strategy: Maintain a low-impedance return path for switching currents to avoid noise and ringing.

Note: Minor layout tweaks can significantly reduce reverse recovery-induced voltage spikes, improving circuit reliability.

2. Component Selection and Prototyping Tips

-

Voltage Rating: Choose diodes that exceed the maximum transient voltage to ensure safe operation without compromising speed.

-

Reverse Recovery Time: Prioritize trr performance to minimize switching losses in high-frequency operations.

-

Forward Voltage Considerations: Balance slightly higher forward voltage against efficiency requirements for your application.

-

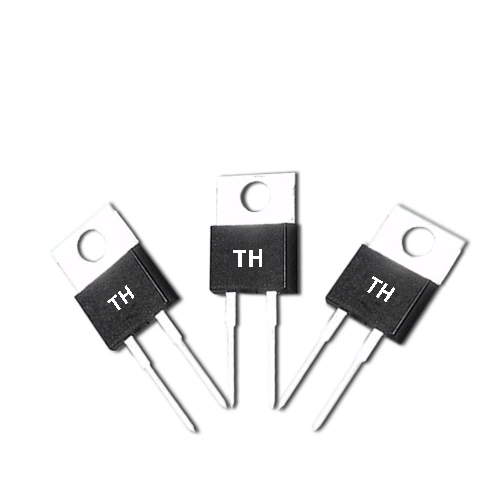

Package Selection: Evaluate compact packages (SMA, SMC, SOD-123, etc.) to fit high-density OEM boards and optimize heat dissipation.

Prototyping Tip: Keep a selection of FRDs with varying trr and voltage ratings to quickly iterate and test circuit performance under different load conditions.

3. High-Frequency Switching Optimization

FRDs are particularly sensitive to switching dynamics. To ensure stable operation:

-

Snubber Networks: Implement RC or RCD snubbers to limit voltage overshoot and ringing caused by reverse recovery currents.

-

Gate Drive Tuning: Adjust MOSFET or IGBT gate resistances to match FRD switching characteristics, balancing speed and thermal stress.

-

Decoupling Capacitors: Place capacitors near diodes to reduce transient spikes and improve EMI performance.

Tip: During prototype testing, monitor waveforms with high-bandwidth oscilloscopes to validate recovery behavior and switching efficiency.

4. Accelerating Prototyping Workflow

-

Modular Testing: Use plug-in diode modules to test multiple configurations without redesigning PCBs.

-

Simulation-Driven Iteration: Pre-validate FRD integration using circuit simulators to reduce trial-and-error cycles.

-

Thermal Profiling: Map junction temperatures in real-time during high-frequency operation to catch hotspots early.

-

Documentation: Record diode performance against switching loads to streamline future OEM projects.

5. Reliability and Longevity Considerations

-

Voltage Overshoot Protection: Ensure FRDs are paired with adequate transient suppression components.

-

Current Handling: Design traces and vias to manage peak currents without excessive voltage drop or heating.

-

Environmental Factors: Consider ambient temperature ranges, airflow, and potential derating in high-stress industrial environments.

Note: Proper integration not only improves performance but also extends component lifetime and reduces warranty issues.

FAQ

Q1: Can FRDs replace Schottky diodes in high-voltage circuits?

A1: Yes, for applications requiring higher voltage ratings while maintaining fast recovery. Schottky diodes have lower forward voltage but limited voltage handling.

Q2: How to reduce reverse recovery spikes?

A2: Optimize PCB layout, add snubber networks, and tune gate resistances to control switching transients.

Q3: What package type is best for compact OEM boards?

A3: SMA or SOD-123 packages are preferred for tight spaces, balancing thermal performance and ease of integration.

Conclusion

Integrating super fast recovery diodes into OEM circuits requires careful attention to layout, switching dynamics, thermal management, and modular prototyping strategies. By prioritizing component selection, optimizing trace design, and using high-frequency testing, engineers can accelerate prototype development while achieving stable, reliable high-performance operation. Proper implementation ensures lower switching losses, minimal voltage overshoot, and extended component longevity, enabling faster time-to-market for OEM designs.

www.tonghua-electronics.com

Tonghua Electronics Co, Ltd.