In the pharmaceutical industry, where precision, hygiene, and consistency are critical, the choice of processing equipment directly impacts product quality and operational efficiency. One such vital piece of equipment is the Bottom Vacuum Emulsifier Mixer — an advanced mixing solution used widely in the production of creams, ointments, suspensions, and emulsions.

Orisun, a dedicated enterprise engaged in mechanical design and manufacturing, plays an essential role in delivering high-performance vacuum emulsifier systems tailored for pharmaceutical needs. With cutting-edge technology and industry expertise, Orisun is helping pharmaceutical manufacturers scale innovation while maintaining regulatory compliance.

What is a Bottom Vacuum Emulsifier Mixer?

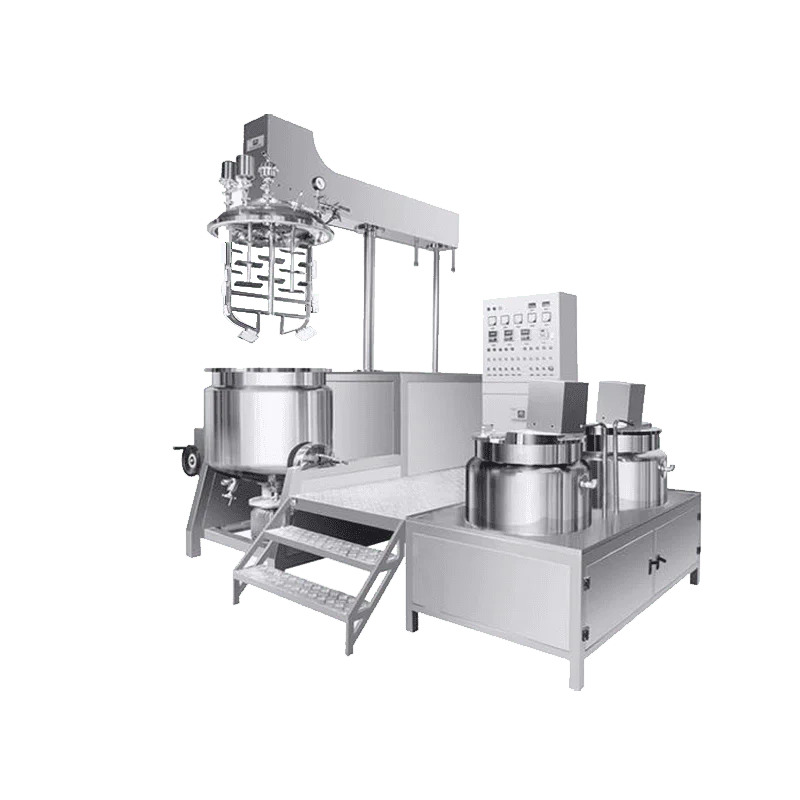

A Bottom Vacuum Emulsifier Mixer is a specialized mixing device that combines vacuum technology, high-shear emulsification, and bottom-mounted mixing into one compact, efficient system. Unlike conventional top-mounted mixers, the bottom design enhances vortex formation, reduces mixing time, and improves homogenization efficiency.

Key features often include:

Bottom-mounted high-shear mixing head

Vacuum deaeration system to eliminate air bubbles

Heating/cooling jacket for temperature control

Touchscreen automation control for precision batch management

Sanitary design complying with GMP (Good Manufacturing Practices)

Applications in Pharmaceutical Manufacturing

The mixer is used in a variety of pharmaceutical applications, including but not limited to:

1. Creams and Ointments

Hydrophilic and lipophilic phases are emulsified into uniform, stable creams. The vacuum prevents oxidation and ensures a smooth, air-free finish.

2. Lotions and Gels

Accurate blending of active ingredients and excipients into transparent or opaque gels with fine consistency.

3. Syrups and Suspensions

Prevent sedimentation by achieving a homogeneous dispersion of solids in liquids. The bottom mixer ensures full powder wetting and eliminates clumps.

4. Vaccines and Biopharmaceuticals

In some cases, emulsifier mixers can be used in early formulation phases for vaccine adjuvants or protein dispersions under sterile environments.

Benefits of Bottom Vacuum Emulsifier Mixers

✅ Efficient Emulsification

The bottom high-shear head disperses immiscible liquids (e.g., oil and water) into micro-droplets, forming stable emulsions essential for pharmaceutical formulations.

✅ Air-Free Processing

Vacuum operation eliminates trapped air, which is crucial for:

Improving shelf life

Avoiding oxidation

Preventing microbial contamination

✅ Improved Hygiene and Cleanability

The mixer is typically designed with CIP (Clean-in-Place) and SIP (Sterilize-in-Place) features, making it ideal for sterile manufacturing environments.

✅ Precise Control and Automation

Advanced HMI/PLC systems allow operators to monitor parameters such as mixing speed, temperature, vacuum level, and processing time, ensuring batch-to-batch consistency.

✅ Time and Cost Efficiency

Faster mixing and deaeration reduce processing times, energy consumption, and operator involvement — optimizing production cycles.

Orisun: Engineering Excellence in Emulsifier Mixer Design

Orisun brings years of mechanical design expertise and manufacturing know-how to develop customized Bottom Vacuum Emulsifier Mixers that meet the unique requirements of the pharmaceutical sector.

What Sets Orisun Apart?

Tailored Engineering: Orisun provides personalized designs based on customer formulations and facility layout.

Compliance Ready: Equipment is designed in accordance with GMP, FDA, and CE standards.

Material Excellence: Use of high-grade stainless steel (316L/304) with mirror-polished internal surfaces.

Integrated Systems: Ability to integrate heating, cooling, vacuum, and automation into one modular system.

Global Support: Orisun offers installation, training, and maintenance services to ensure seamless operation.

Whether you're scaling up a new drug product or upgrading existing processing lines, Orisun's mixers provide the reliability, performance, and hygiene required for pharmaceutical-grade manufacturing.

Conclusion

In an industry where precision and purity are everything, Bottom Vacuum Emulsifier Mixers represent a cornerstone of modern pharmaceutical production. From reducing processing time to ensuring consistent product quality, these machines are indispensable for high-stakes manufacturing environments.

Orisun, as a forward-thinking machinery design and manufacturing company, continues to empower pharmaceutical producers with innovative, customized emulsifying solutions that drive both quality and efficiency.

Top Features of Bottom Vacuum Emulsifier Homogenizer Mixers for Industrial Use

www.orisunmachinery.com

Orisun